Checking clutch components is generally not part of the pre-ride check nor is it really something addressed when performing routine maintenance.

Usually, the first sign of trouble is when the gears slip. Since most seasoned riders can trouble shoot their way from there, because other issues mimic clutch problems, that's quite often when the clutch gets changed, if needed.

Other issues that affect the gears include worn out chain and sprockets and/or inappropriate slack on the chain, a clutch cable that's frayed or not adjusted properly, or the clutch lever needs lubrication or adjusting. Once you've ruled out these problems, the likely cause is the clutch.

Therefore, when the gears slip, you'll need to use a micrometer (or digital vernier caliper) to check the manufacturer's recommended thickness of the following:

- Drive plate (or Steel) thickness

- Pressure plate surface

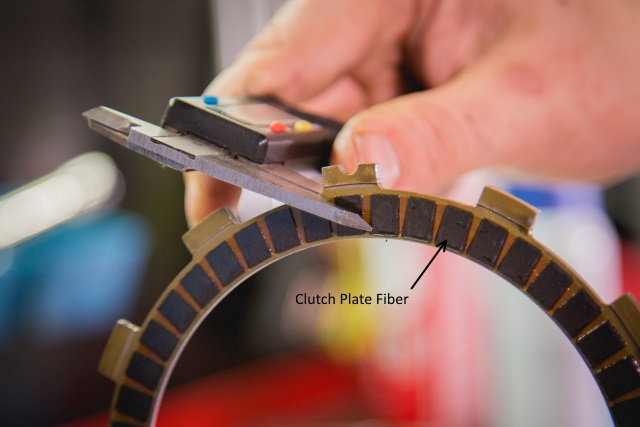

- Fiber thickness on the pads of the clutch plate

The clutch plates and drive plates make up the clutch pack. The clutch plate fiber (looks like cork) lines the surface of the plate. If any components display thickness below recommended limits it's time to replace the clutch. If the drive plate shows warpage beyond the recommended limits, you'll also need to replace the above segments.

Checking the thickness of the Pressure Plate using a digital vernier caliper

Keep in mind that most clutch kits do not include a cover gasket, pressure plates, the hub and basket together. You'll have to buy everything separate including the clutch pack. However, a typical clutch replacement changes just the clutch pack consisting of the drive plates and clutch plates, the pressure plate and springs. Therefore similar to the chain and sprockets, replace the clutch pack, springs and pressure plate together.

Using a Feeler Gauge to check for warpage on a Drive Plate

A major clutch overhaul, which includes changing the hub and basket adds a bit more time and effort but isn't done as often. Visually inspect the hub and basket while installed on the bike. If there's any indication of wear pull them and check to see if they are in spec with the manufacture recommended wear limits. The micrometer used to measure the pressure plate and fiber thickness on the clutch plates is also used for measuring the hub.

Mechanic's Tip: Pressure plate wear, broken fibers plates or warped steel plates are also indication of clutch basket and hub wear.

Though changing the clutch pack isn't an arduous process finding out it is necessary during pre-race practice at the track can throw some unnecessary complications your way. If you don't have a spare clutch pack, for example, good luck grabbing the holeshot. Otherwise you've got to get back to the pits and get to work...real fast.

Use a digital vernier caliper to check the thickness of the Clutch Plate Fiber

Eliminate this hassle by incorporating a regular clutch check into your maintenance schedule. You don't need to do this every time since the clutch lasts a number of rides and veteran riders usually know when it's getting close. It's simple and takes just a few minutes to unlock the clutch cover, pull out the clutch pack, do a quick measure and pop back into place if they exceed the factory specified limits. If you find the clutch needs replacing, you've saved yourself time and a big headache.

For your additional reading pleasure on other related tips: